MOLDINO - Ball End Mill BR2P type | JSR GROUP

BR2P type

Features of BR2P type

Unique insert mounting mechanism and helical cutting edge for greater cutting efficiency

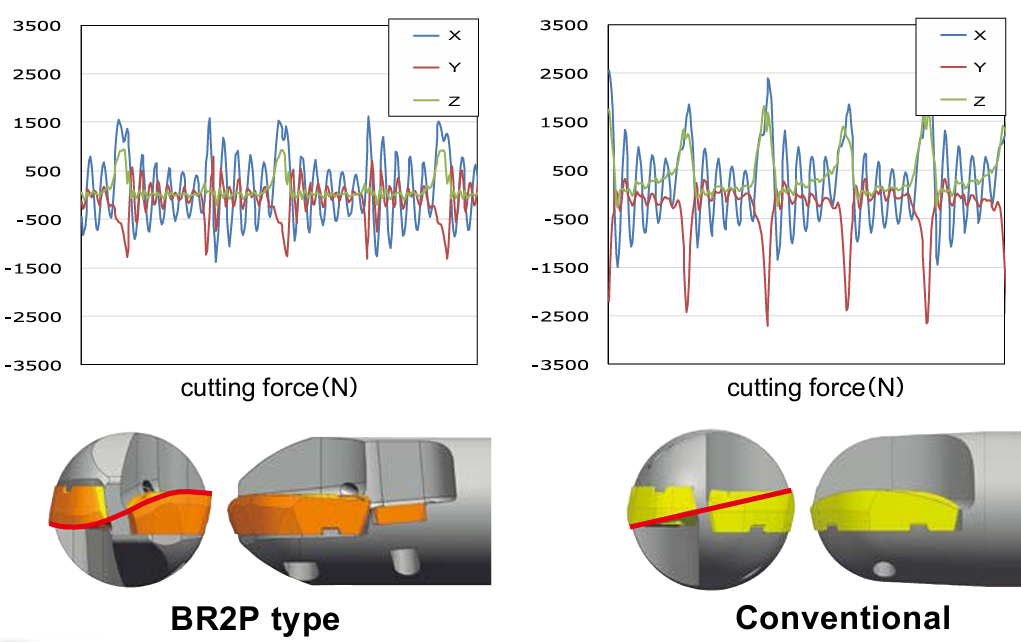

| Issue 01 | Need to set less demanding cutting conditions when using conventional tools due to potential for chattering vibration |

Proposed solutions

The shape of the helical cutting edge reduces cutting resistance, suppresses chattering by mitigating impact on contact with the cutting edge, and helps prevent a rapid increase in cutting resistance.

|

Cutting conditions Work material : S50C(220HB) |

| Point ! | Helical cutting edge to suppress chattering |

| The helical shape of the cutting edge results in improved tool life for BR2P than conventional products by suppressing chattering vibration. |

Cutting conditions Work material : SKD61(45HRC) Slant angle: 5° |

|

|

After six hours of cutting : Normal wear |

After an hour of cutting : Severely damaged; almost completely consumed After an hour of cutting : Severely damaged; almost completely consumed |

|

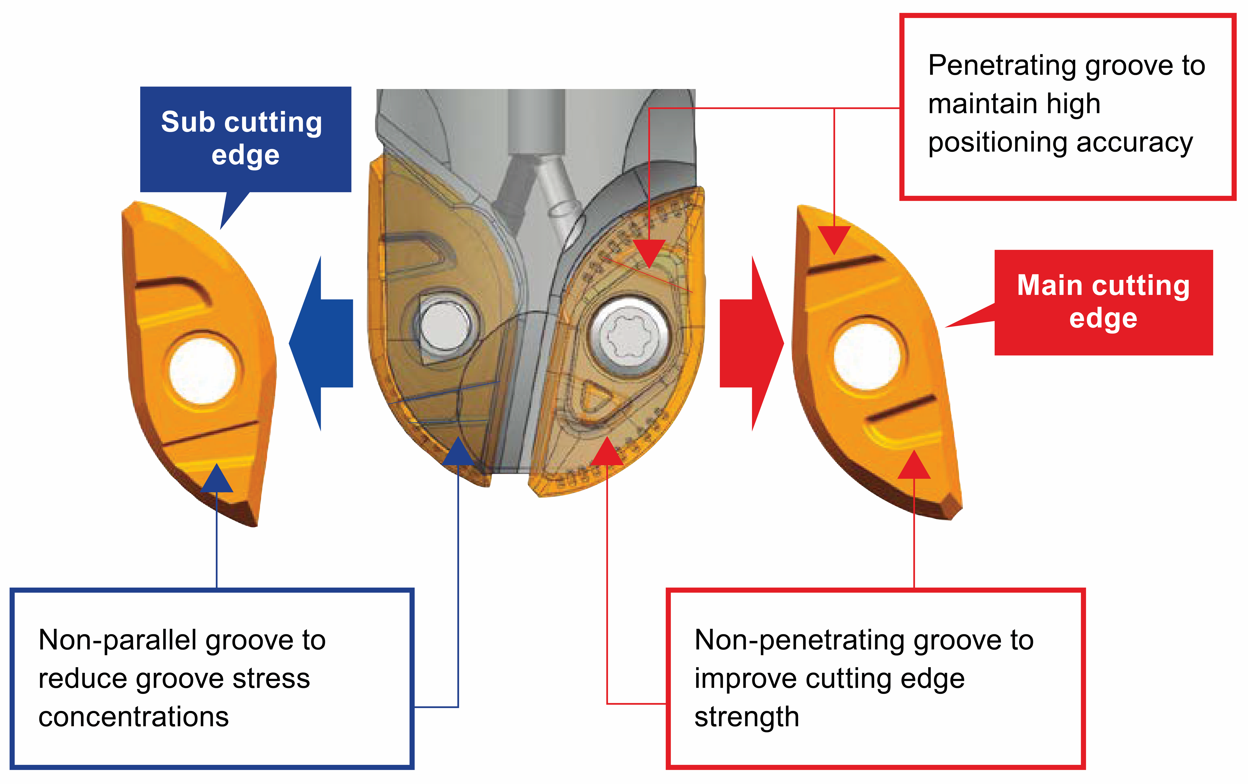

| Issue 02 | Unable to increase cutting conditions, since more demanding cutting conditions could potentially damage the insert. |

Proposed solutions

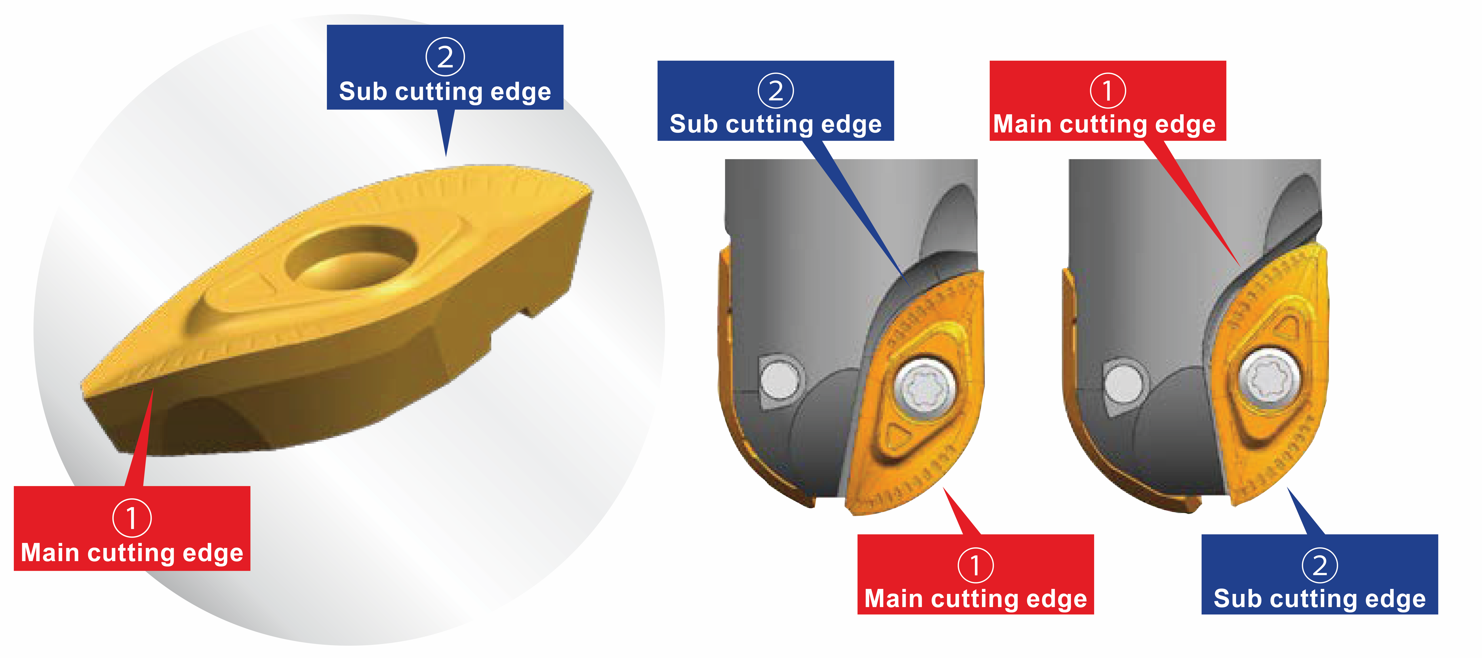

A non-penetrating groove on the bottom surface of the main cutting edge secures cutting edge strength. (The bottom surface of the main cutting edge receives the greatest cutting resistance.) In addition, a penetrating groove on the constraint surface of the main cutting edge maintains high positioning accuracy.

| Point ! | Two-in-one integrated insert for improved convenience |

Conventional products require two types of inserts (a main insert and a sub insert ). In contrast, BR2P uses a single integrated insert for improved handling.

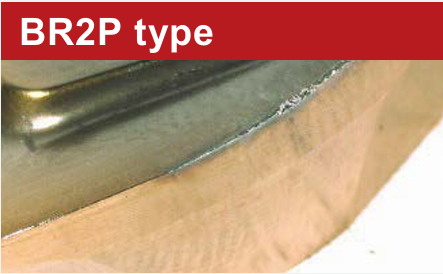

| Issue 03 | Tool life is reduced due to the difficulty in cutting the overlay welding material used for the press die repair. “Are there any suitable tools?” |

Proposed solutions

The BR2P enables smooth cutting of overlay welding materials with variable cutting depths because the helical cutting edge suppresses cutting resistance even as cutting depth increases.

|

Cutting conditions Work material : Nodular cast irons |

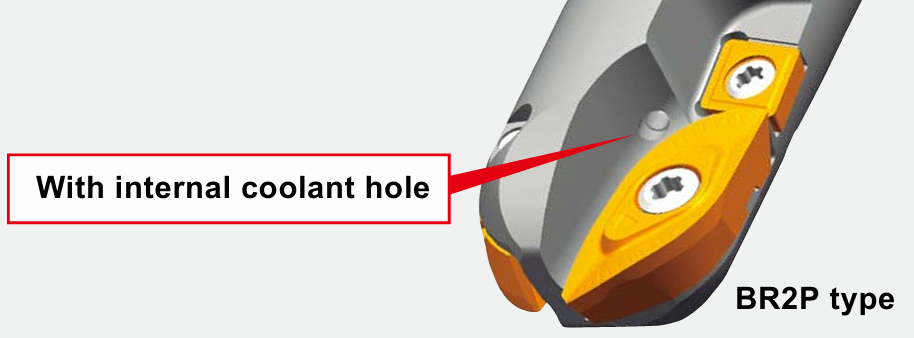

| Point ! | Internal coolant improves chip evacuation |

The BR2P has coolant holes for all diameters of the modular and shank types (except MT shank). The internal coolant improves the chip evacuation, reducing chip biting.

| Issue 04 | Is there a tool that can be used stably for the roughing cut of large-sized dies? |

Proposed solutions

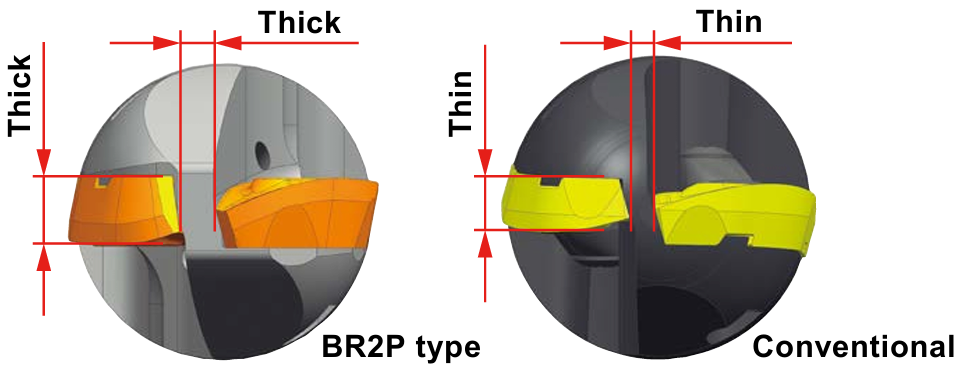

Large φ40 and φ50 tools are available for the BR2P. In addition, improved body and insert rigidity helps suppress chipping.

Increasing the body center thickness improves the rigidity of the body. Increasing the insert thickness enables to suppress sudden chipping under higher efficiency machining.

|

Cutting conditions Work material : S50C(220HB) Machine : Vertical type (BT50) Tool Cutter : BR2P5063C508-200-120 Insert : ZPET250R-N JP4120 Cutting speed : V c=250m/min Revolution : n=1592min-1 Feed per tooth : f z=0.23mm/t Feed speed : V f=732mm/min Radial depth of cut : ap×ae=25×15mm Air |

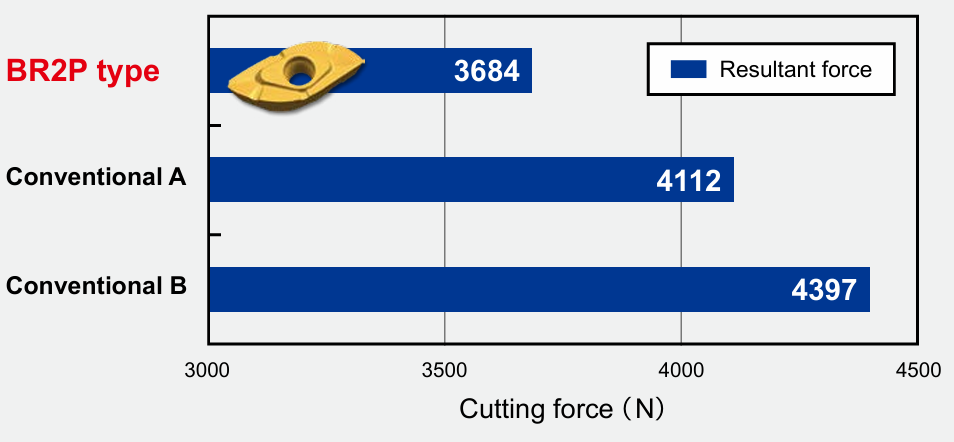

| Point ! | Nicked inserts reduce cutting resistance |

Using a φ50 nicked insert, the BR2P reduces cutting resistance compared to conventional products.

|

Cutting conditions Work material : S50C(220HB) |